SpecSoft has a deep packaging knowledge and broad expertise which, coupled with a modest overhead, allows the development of custom machinery at a reasonable price. Although our standard products are all customized to each application, there is always a need for some automation for which machine designs do not exist. Listed below are some examples of our custom machinery designs.

Log Loaders

A customer needed a machine to load logs of meat into a meat slicer. For ergonomic and safety reasons it was undesirable to do this task manually. A machine was designed to allow the operator to load the meat logs into it in an ergonomic fashion. The logs were then lifted into the slicer automatically.

Web Folders

A customer needed a folder to fold the sides of a web of craft paper over during a constant motion web processing operation. Folders were designed and mounted on a servo controlled linear slide that gave the customer quick set up for various web widths and very high speeds.

Ink Cartridge Pick and Place

Ink cartridges in blisters are unscrambled by a bowl feeder, inspected for integrity, picked up by a vacuum piccker and placed into the core of a roll of labels from the outfeed of a printing press. Products not passing inspection are rejected.

Hot Dog Pick and Place

The machine grabs 12 four-packs of hot dogs from the output of a wrapper, then loads floating buckets each with a stack of two four packs. The floating buckets are then conveyed to a horizontal sweep to transfer the hot dogs into the buckets of a cartoner.

Watch Hot Dog Pick and Place Video

http://www.youtube.com/watch?v=Ll873LZ34t0

- This lengthy video shows a pneumatic pick and place unit picking up packages of hot dogs and collating them for loading into the buckets of a cartoning machine. The hot dog packages have four hot dogs per package, individually sealed with perforations between the individually sealed hot dogs. The wrapper produces 12 packages per index – three lanes of four packages each. The cartoner must package two layers of hot dog packages per carton. The system operates at 240 hot dog packages per minute.

Product Orientors

Receives the output of a freezer of randomly oriented frozen dinners, orients them and transfers them into the infeed of a casepacker.

Load Lifter

A manufacturer of concrete pipe fittings required a machine to lift a load of concrete fittings off a pallet to allow a stretch wrapper to wrap the load and then place the wrapped load back on the pallet. A machine was designed and installed in a pit below the stretch wrapper to accomplish the task.

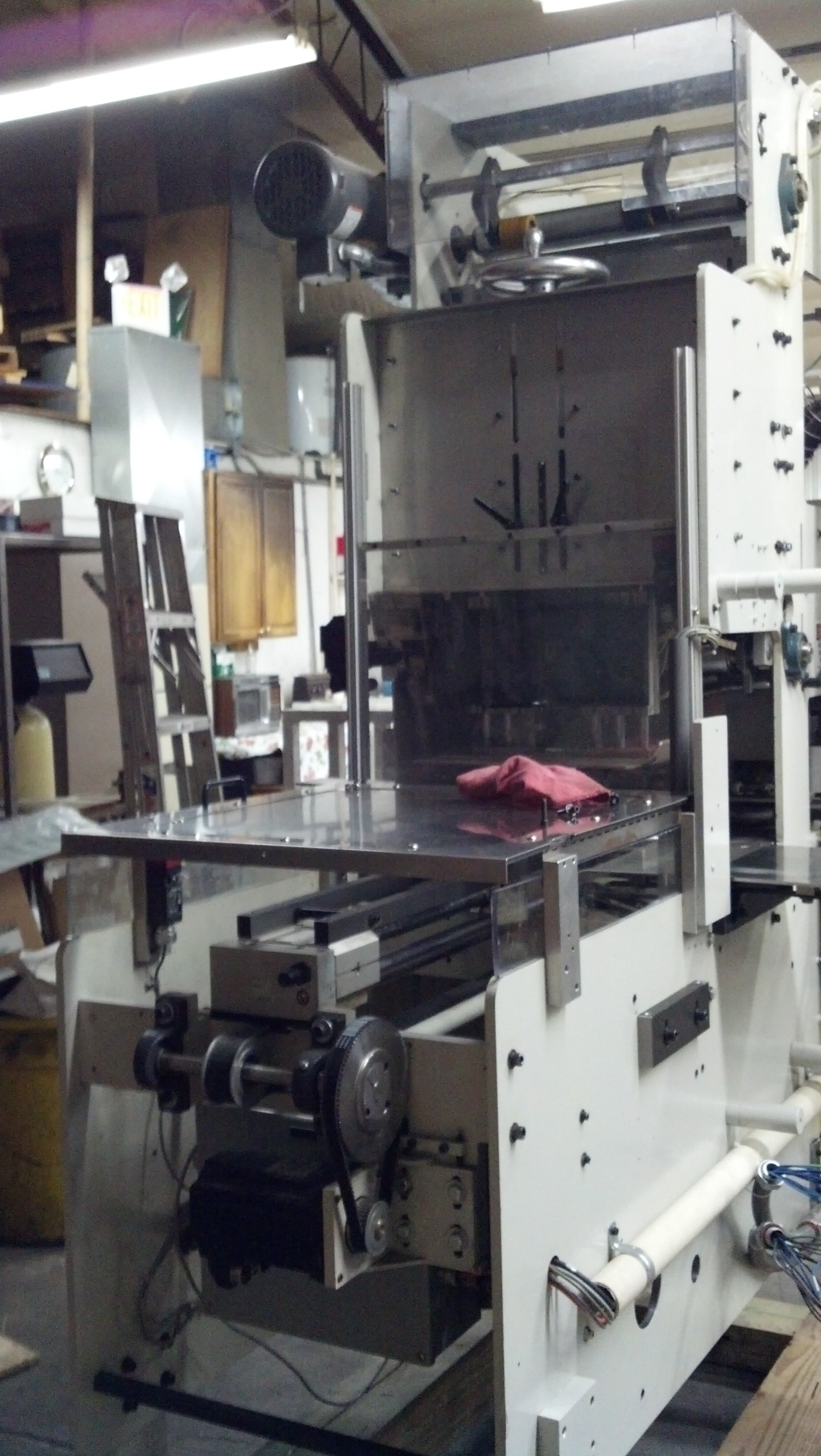

Banding Machine

This machine recieves an input stream of paper bags, stacks out a set amount, and bands them together.

Watch Banding Machine Video

https://www.youtube.com/watch?v=cArtaiPakeE

Specialty Conveyors

We manufacture conveyors that fit into existing packaging equipment.